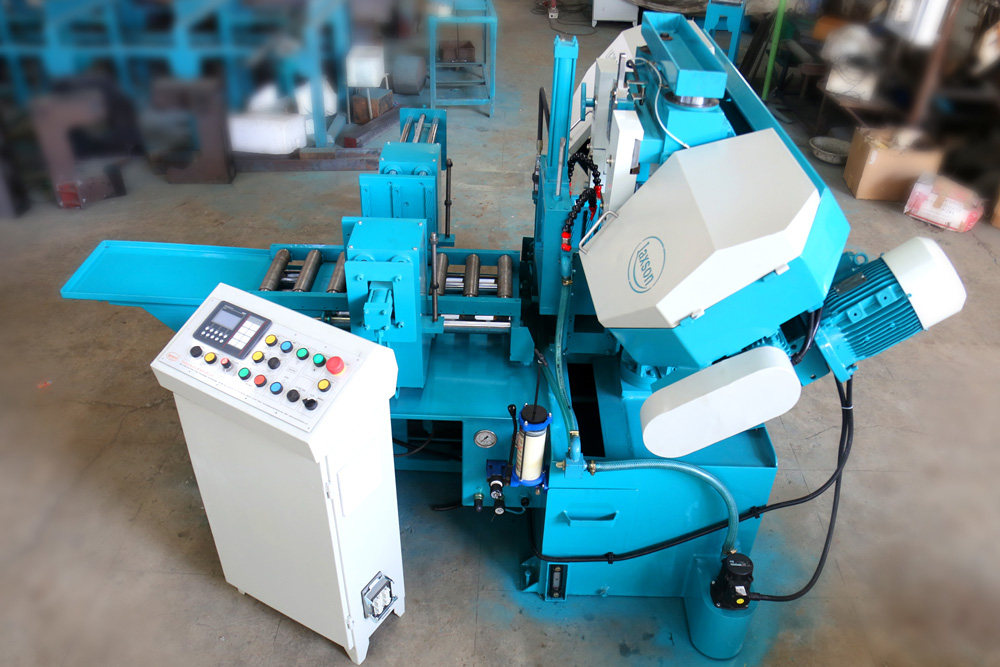

LK-241 DCA

- PLC control for all electric and hydraulic functions

- Shuttle Type Automatic Job Length Feeding

- Floating shuttle vise for handling of bent job

- Automatic work height control and fast approach

- Power driven Chip removal Wire brush assembly

- Hydraulic Blade Tension

- Split main vise for better gripping

- Idler Wheel Motion Detector with Blade Stalling and Breakage shut off

- Roller Bearing / Carbide wear pad Blade guide system

- Bi Metal Bandsaw Blade

Description

| Cutting Capacity | 240 |

| Round (mm) | 240 |

| Square (mm) | 240 |

| Blade Dimensions(mm) | 3760 x 27 x 0.9 |

| Blade Linear Speed(meter/min.) | 20 -100 RPM |

| Power Req. – Saw Drive (440V AC, 50Hz) Kw/Hp | 2.2/ 3.0 / 1440 RPM |

| Coolant Pump (440V AC, 50Hz) Kw/Hp | 0.12 / 0.16 / 2800 RPM |

| Wire Brush Motor (440V AC, 50Hz) Kw/Hp | 0.18 / 0.25 / 1440 RPM |

| Hydraulic Tank Capacity (Liter) | 30-40 liter |

| Coolant Tank Capacity ( Liter | 80 liter |

| Shuttle Bar Feed Stroke (mm) | 350 |

| Bundle Cutting W x H mm (*optional) | 210 x 150 |

| Dimensions (LxWxH) mtr. | 2 x 2.5 x 1.3 |

| Weight (kg) | 1900 |

OPTIONAL ACCESSORIES

- A.C. Drive for Infinitely variable speed control

- Bundle cutting attachment

- Chip Conveyor

- Job Roller Stand

- Wire Brush

- Bi-metal Bandsaw blade

- Variable Vise pressure for thin walled job